Slot die coating viscosity range, pacific poker 888 android, korean casino news, find friend pokerstars Patented manifold and lip configuration for extremely uniform coating.

Slot-die Coating Theory Design Applications Ossila

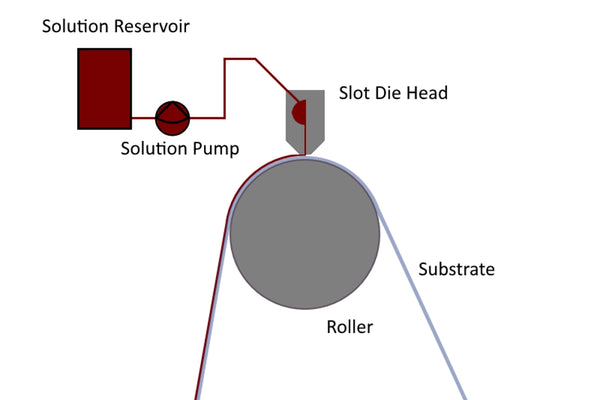

Printing technologies include gap coating, slot die coating, roll coating, and gravure coating [15].

Slot die coating viscosity range. Slot die casting process at different operating conditions, in the past. Indeed, slot die coating technology is currently a widely used method for the production of optical films with high precision. Yasui seiki precision slot die is suitable for coating thicker layers with higher viscosity coating fluids.

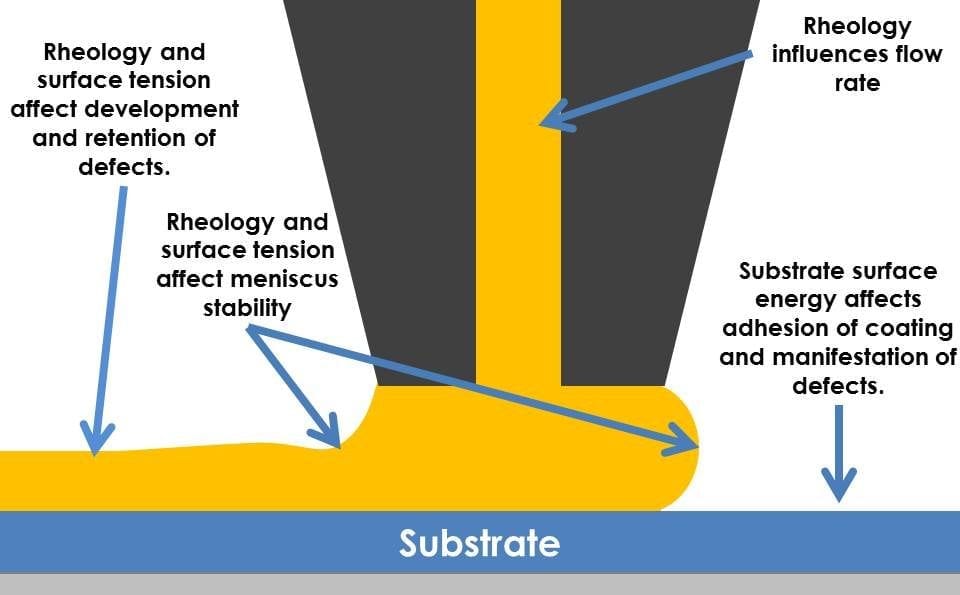

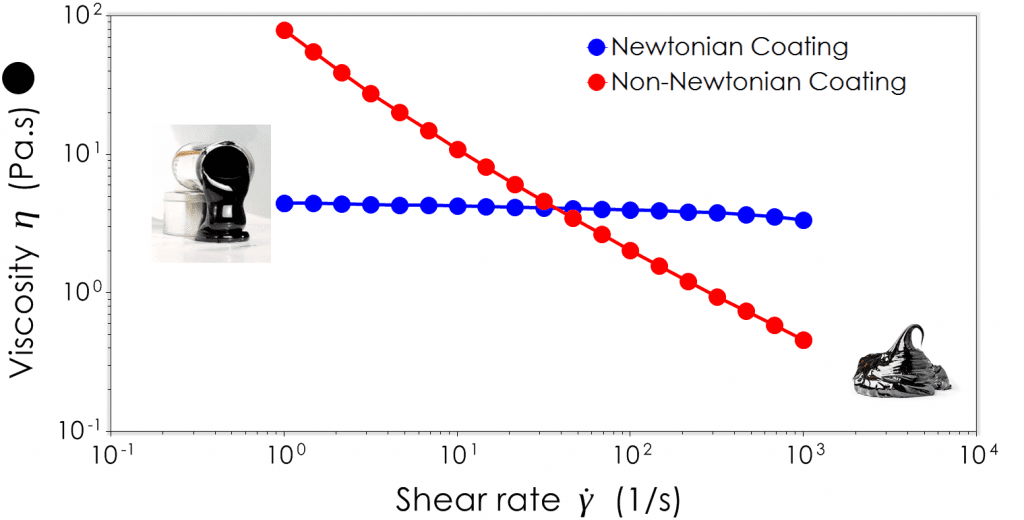

Outside the proper ranges, coating defects will occur, such as ribbing, dripping, rivulets, and. The rheology of your coating is key when deciding the appropriate range of operating parameters including coating speed, flow rate, vacuum pressure, coating gap and liquid viscosity. 2 shows the th e,w (red plane), and th m,w (cyan plane) according to the coating gap, flow rate, and viscosity of ysz.

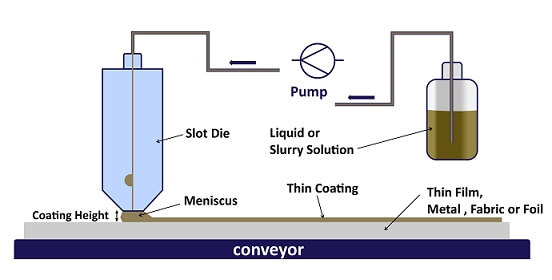

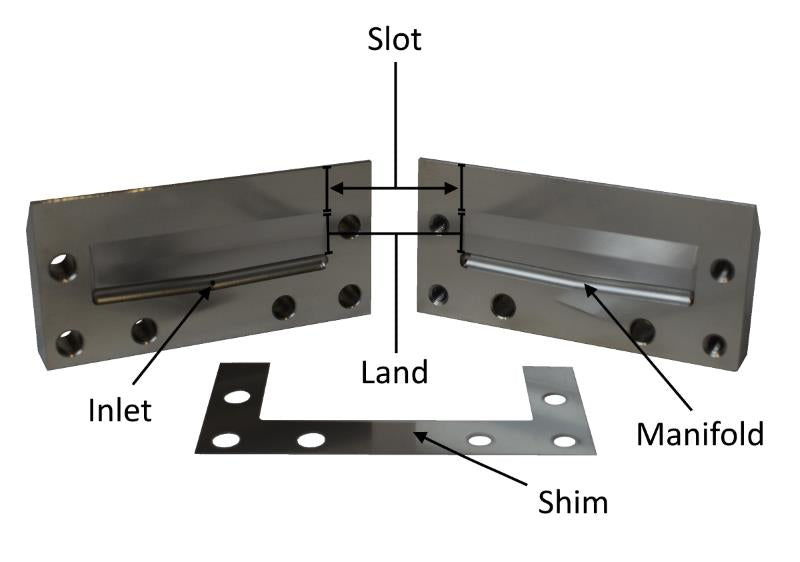

High precision coating, low viscosity thin coating, high coating quality, good stability, low dependence on gap precision. In this method, a film is formed using a gap introduced between the die and the substrate on the back roll. The number of strips ( n ) is one.

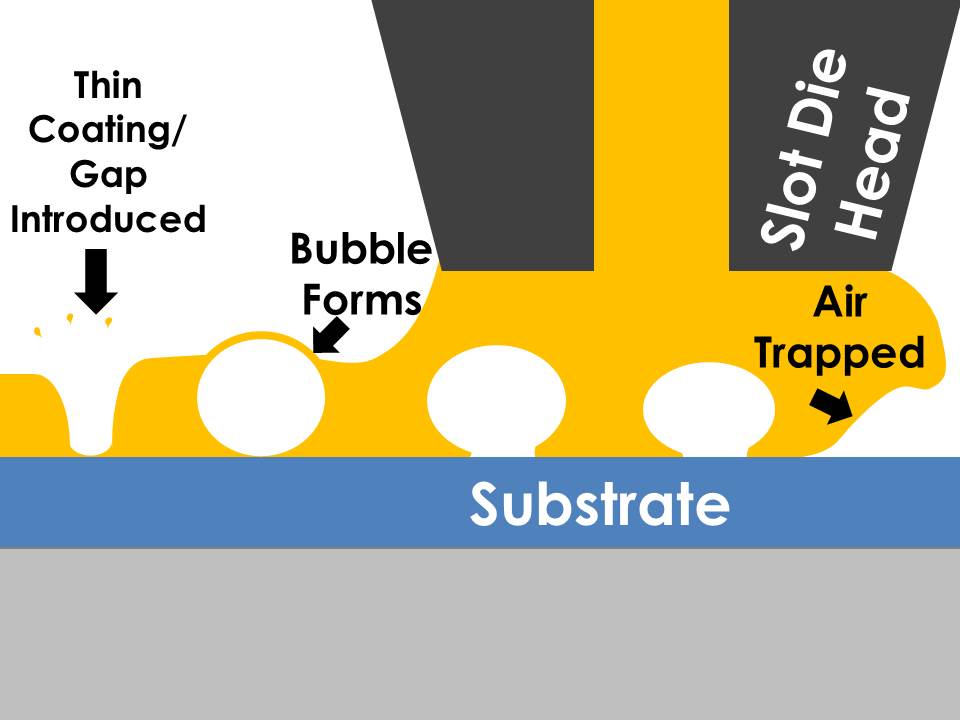

However, few studies exist focusing on the investigation of the air engulfment phenomenon, especially for relatively high viscosity shear thinning materials. All other parameters work to improve the uniformity and stability of the coating. Slot die coating emerges as an efficient, controllable alternative to roll coating and other conventional methods of applying fluids to web substrates.

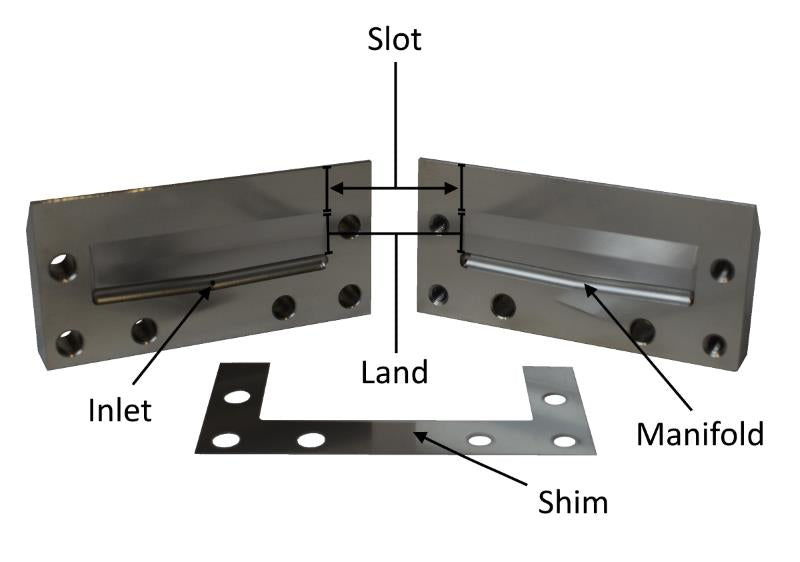

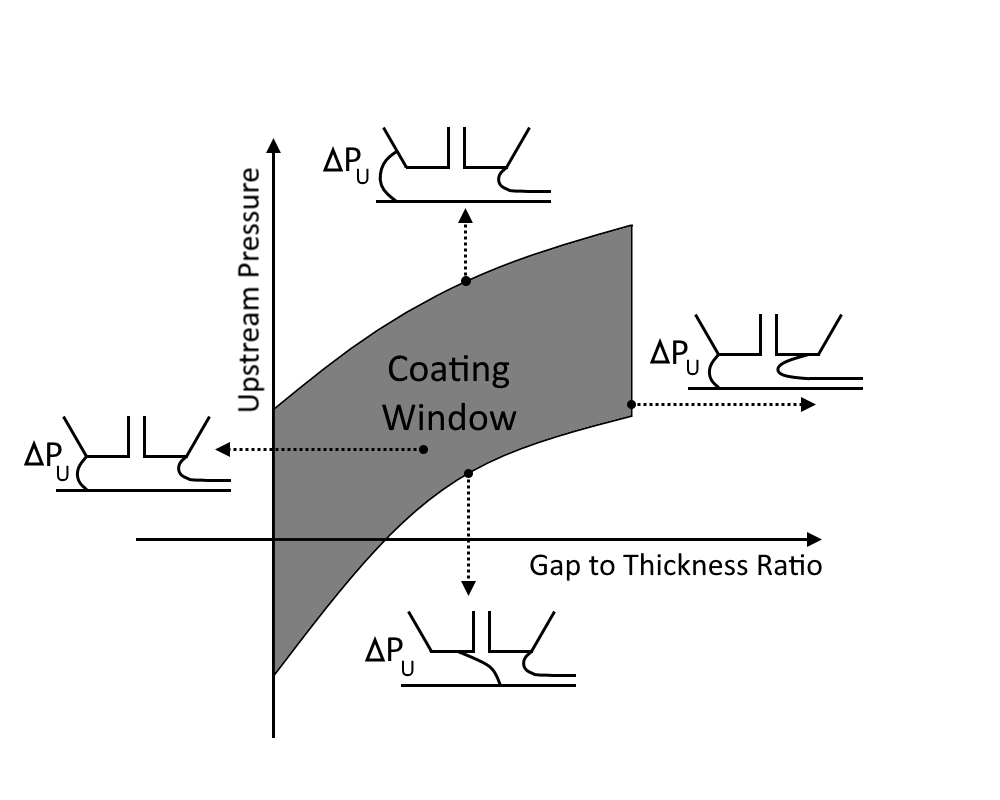

The heads have been designed to provide outstanding coating properties, whilst being compatible with all coating machines. This smart guide to caribbean stud poker strategies will help beginners learn the basics. In the field of organic electronics, the precise control of coating thickness and coating width is crucial.1 the slot die coating method is applicable to precisely deposit a wide range of wet film thicknesses from the range of one micron2 to hundreds of microns.1,3,4,5 however, coating defects might occur6,7,8 if the process parameters are not chosen appropriately within a specific process window.

This means that the wet film thickness is determined by the amount of solution placed onto the substrate. Thus, slot die coating is an important film fabrication method for applications where precise coating is required. Reference range of application coating speed:5~500m/min viscosity.

Inequality (15) is the coating speed range. Caribbean stud slot die coating viscosity range is a very popular form of poker. The mechanism by which air entrains in the domain has been studied numerically and

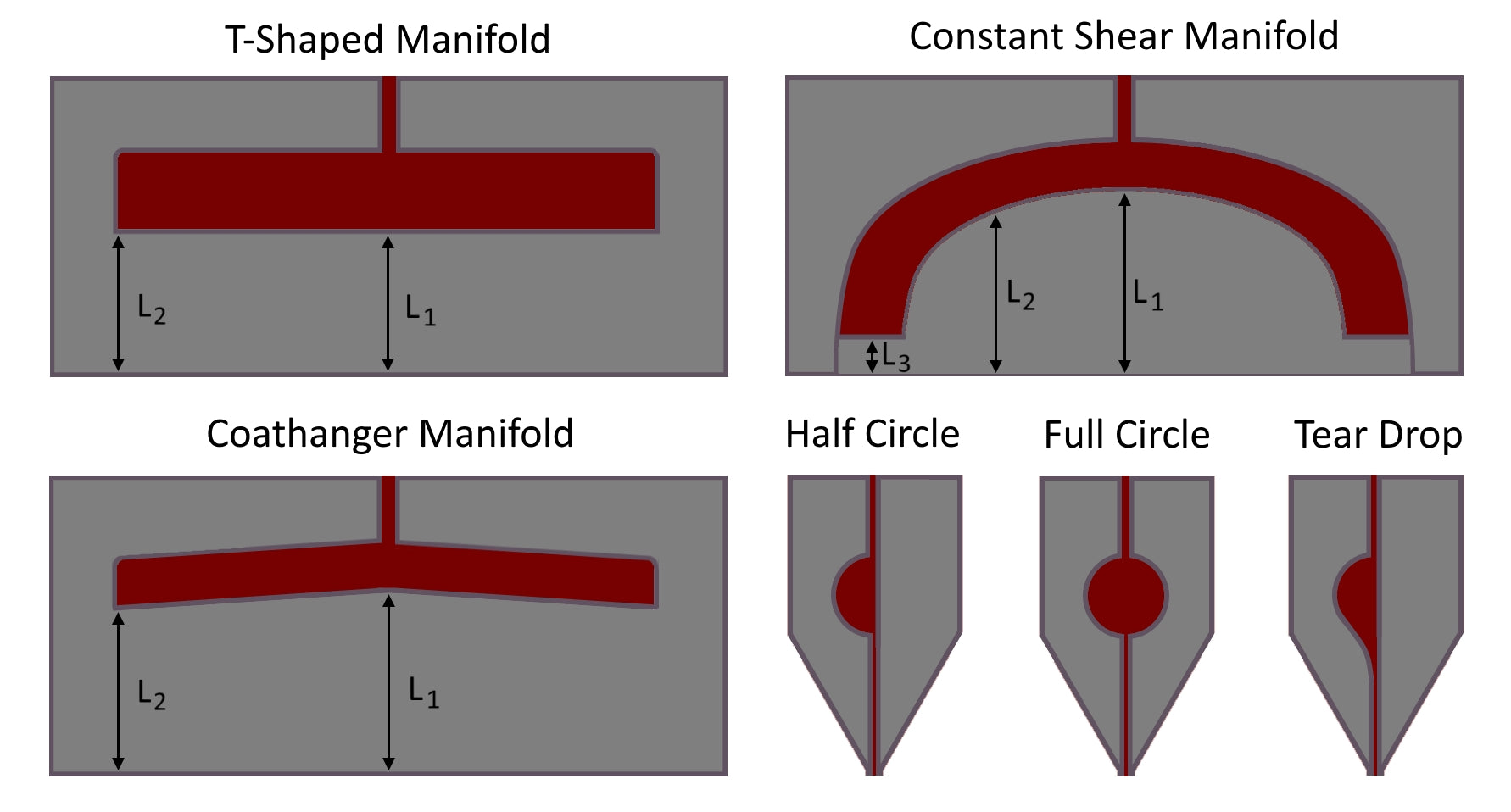

Slot width, and die orientation. A major concern in slot die coating processes is how to determine the operating limits to set the appropriate range of operating parameters, including coating speed, flow rate, vacuum pressure, coating gap, liquid viscosity and surface tension, etc. In addition, they are simple to use and.

Slot Die Coating Rheology - Expert Analyses From The Rheology Lab

Slot-die Coating Theory Design Applications Ossila

Scheme Of The Slot Die Printing Head Depositing A Curtain Of Ink Download Scientific Diagram

Httpswwwfomtechnologiescomwp-contentuploads202008fom-technologies-faq_refpdf

Blade Coating And Slot-die Coating Ab Schematic Illustration Of Download Scientific Diagram

Slot-die Coating Theory Design Applications Ossila

Httpswwwfomtechnologiescomwp-contentuploads202008fom-technologies-faq_refpdf

Die Coater Technical Expertise Hirano Tecseed Co Ltd

A Schematic Of Slot Die Coating B Schematic And C Photograph Of The Download Scientific Diagram

Slot Die Coating Rheology - Expert Analyses From The Rheology Lab

Slot Die Coating Of Battery Slurry

Ac Schematic Representation Of Slot-die Coating On Rigid Glass A Download Scientific Diagram

Slot Die Coating Of Polybenzimiazole Based Membranes At The Air Engulfment Limit - Sciencedirect

Simulations Of The Slot-die Coating Process Performed By Using The Download Scientific Diagram

Slot Die Coating Rheology - Expert Analyses From The Rheology Lab

Slot-die Coating Theory Design Applications Ossila

Slot-die Coating Theory Design Applications Ossila

Slot-die Coating Theory Design Applications Ossila

Komentar

Posting Komentar